OSCARMAX|EDM Machine Manufacturer for Mold, Aerospace, and Automation

EDM Machine / Micro Drill EDM / Die Sinker EDM

.png)

%E6%89%8B%E5%B7%A5%E7%9B%92%E6%A8%A1%E5%85%B7.jpg?width=5464&height=8192&name=(S)%E6%89%8B%E5%B7%A5%E7%9B%92%E6%A8%A1%E5%85%B7.jpg)

With a focus on innovation, intuitive design, and strict quality control, OSCARMAX supports high-mix, high-precision production with global service reliability—empowering manufacturers to scale intelligently into Industry 4.0.

Precision Behind Every Spark

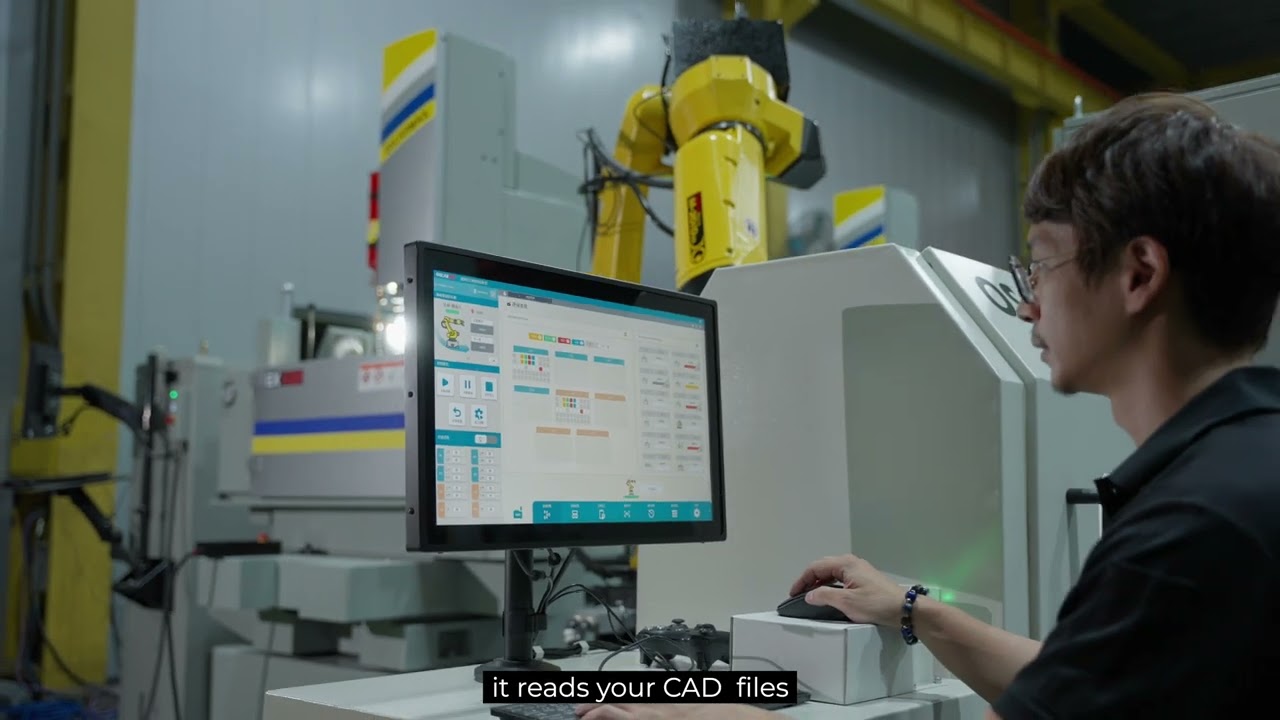

This industrial video highlights OSCARMAX’s core values: Precision × Flexibility × Automation. Micro shots capture intricate machining details, while fast-paced camera movements simulate production rhythm and machine collaboration, conveying reliability and efficiency. Witness how every spark ignites innovation across the international manufacturing landscape.

Smart Machines, Tailored Solutions

Through automated operations, system interfaces, and machining precision, the video visualizes how OSCARMAX’s machines transform production lines with speed, flexibility, automation, and innovation. OSCARMAX’s customizable solution boosts efficiency while maintaining quality, showing innovation, automation, and reliability.

Die Sinker EDM|EX Series

1. OSCARPGM system for automatic machining parameter generation

2. Closed-loop multi-axis control with APC (Adaptable Parameters Control) for real-time spark optimization

3. Windows 10-based touchscreen HMI with ergonomic pendant

4. Integration-ready for modular FMS and automation systems

Applications:

1. Deep-cavity mold production

2. Precision component machining for automotive dies

3. Complex contour die sinking

Micro Drill EDM

1. Micro hole drilling range from 0.1 to 3.0 mm

2. Six-axis control for multi-angle and complex geometries

3. Proprietary waveform editor for spark discharge tuning

4. Real-time voltage, current, and temperature monitoring for machine status diagnostics

5. Optional submersible tank for enhanced hole quality

Applications:

1. Cooling hole drilling in turbine blades (aerospace)

2. Medical micro-tubing and micro-component fabrication

3. Ultra-fine feature machining for electronics

4. Precision drilling in conductive and hard materials

Flexible Manufacturing System (FMS)

1. Modular integration of EDM machines, industrial robots, and pallet systems

2. Visual inventory management, material identification, and cross-station scheduling

3. 3D edge-detection for automatic calibration and process sequencing

4. Centralized control software with EtherCAT communication and API compatibility

5. MES/ERP system integration support

Applications:

1. EDM-based mold and tool production lines

2. Aerospace and high-precision part manufacturing

3. Smart factory deployment with lights-out automation

4. Unified support for multi-brand equipment and workflows

%E6%89%8B%E5%B7%A5%E7%9B%92%E6%A8%A1%E5%85%B7.jpg?width=5464&height=8192&name=(S)%E6%89%8B%E5%B7%A5%E7%9B%92%E6%A8%A1%E5%85%B7.jpg)

Get the Perfect Match

Start your 1-on-1 meetings with OSCARMAX to explore new business opportunities.

Trusted Certifications for Quality Assurance

Stay Ahead of the Curve!

Subscribe Now for Exclusive Insights, Trends, and Offers Delivered Straight to Your Inbox!