Machinery

KING's Solution | LPM & Mold Cleaning Solutions

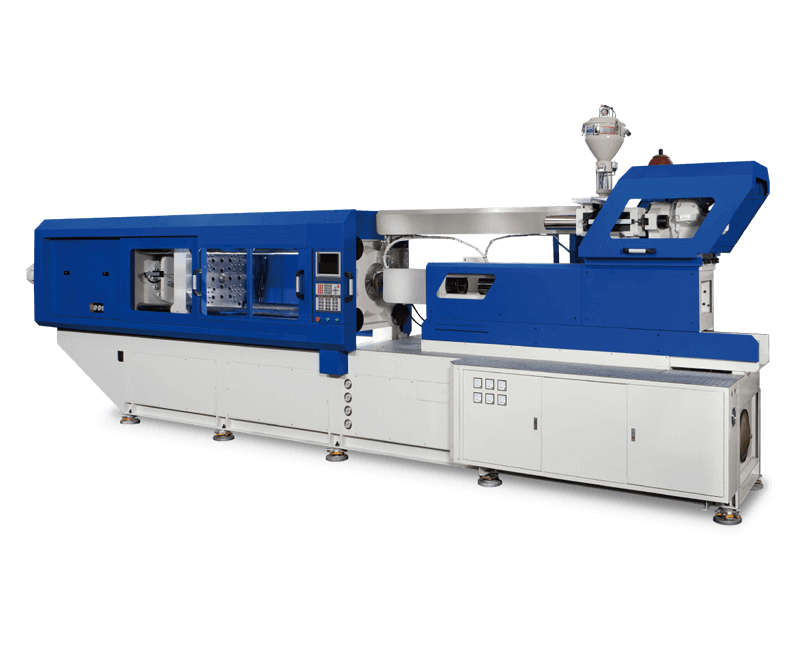

Injection Molding / PET Bottle Manufacturing / Low Pressure Molding

KING's Solution leverages over 40 years of expertise in injection molding to develop and sell eco-friendly, smart manufacturing solutions. With a strategic focus on green sustainability, we aim to become an industry benchmark in low-impact, high-efficiency injection machinery.

It's delivered 1,000+ specialized machines to 30+ countries, helping clients reduce waste, enhance productivity, and adopt recyclable plastics across sectors like EVs, electronics, consumer goods, and silicone processing.

It also creates PET bottle manufacturing solutions with minimal carbon footprints.

5 Gallon PET Preform Injection Molding Machine & Turn-Key Solution

Since 1983, KING'S Solution has specialized in the development of PET preform technology.

With over 30 years of expertise, it offers a comprehensive turnkey solution for 5-gallon PET preform production—from raw materials to finished products.Its solutions deliver cost efficiency, high productivity, excellent quality, and a remarkably low defect rate.

Blowing Defect Rate : as low as 0.5%!

Water Pulse Channel Cleaning Machine

Harnessing patented technology, this machine delivers high-pressure, high-speed pulses of water and air to thoroughly clean the inner walls of mold channels.

The bidirectional pulsed flow effectively dislodges and removes rust, scale, and debris—restoring optimal channel function.

✓ No need to disassemble the mold

✓ Helps reduce annual downtime and boost production efficiency

Applications :

Injection molding / Extrusion / Die casting / Water treatment / HVAC / Water systems / 3D printing

Targets for Cleaning :

Mold water channels / Oil temperature coolers / Chillers / Mold temperature controllers

Low Pressure Injection Molding Turn-Key Solution

The Low Pressure Molding (LPM) process uses hot-melt polyamide materials to deliver efficient, reliable protection for electronic components.

1. Operates at ultra-low pressure : 20–500 psi

2. Provides excellent protection : dustproof, waterproof, and moisture-resistant

3. Faster production cycles: LPM (16–60 sec) vs. traditional potting (8–24 hours)

4. RoHS-compliant raw materials

Ideal for insert molding, PCB overmolding, waterproof cable sealing, and micro switch encapsulation

Get the Perfect Match

Start your 1-on-1 meetings with KING's Solution to explore new business opportunities.

Stay Ahead of the Curve!

Subscribe Now for Exclusive Insights, Trends, and Offers Delivered Straight to Your Inbox!