FKI | From Mono to Multi-layer. From Blow to Lamination — Total Extrusion Solutions.

Blow Moulding / Cast Film / Extrusion Lamination

Fong Kee International Machinery Co., Ltd. (FKI) is Taiwan’s leading plastic extrusion machinery manufacturer, established in 1953 by founder C.C. Wei. With exports to over 120 countries, FKI offers a wide range of equipment including blow moulding, blown film, cast film, sheet making, and extrusion lamination machines. All machines are ISO 9001:2015 certified and CE marked.

Recognized for its reliability and innovation, FKI aims to be a top global brand in plastic extrusion. Backed by advanced technology, decades of experience, and a solid organizational structure, FKI continues to deliver high-quality solutions that meet evolving customer needs.

Presenting a Renewed Brand Image - Brand Video

This brand film introduces a refreshed visual language with a faster, more focused rhythm, clearly communicating Fong Kee’s manufacturing capabilities and professional expertise. Marking the beginning of a new leadership chapter, the film strengthens brand credibility and presents the company with a renewed international image—aligned with its latest appearance at K Show.

Bringing Machine Functions to Life - Product Video

The product film presents end-use application scenarios to help buyers understand typical application contexts. Through the use of close-up live-action footage alongside 2D animations, functional sections and their corresponding machine parts are indicated on screen. Relevant machine data is also presented to support a clear and accessible level of technical understanding.

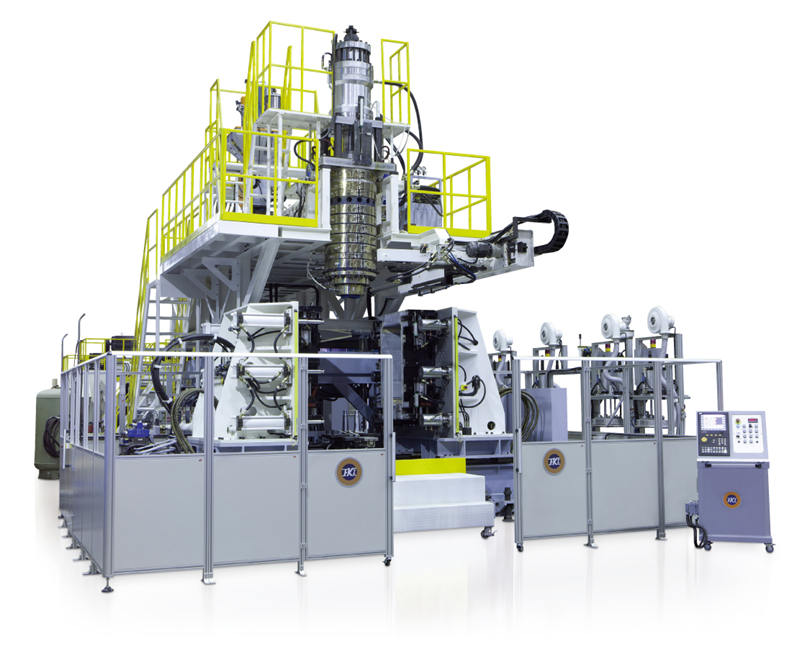

FKI-Accumulator Head Blow Moulding Machine

● Designed for closed-neck L-ring drums (120–250 liters)

● Grooved feeder extruder processes UHMW-HDPE up to 380 kg/hr

● LK-type clamping unit with six-point locking & proportional valve speed control

● Blow pin with unscrewing function for threaded necks

● 3DX radial parison control reduces drum weight and improves quality

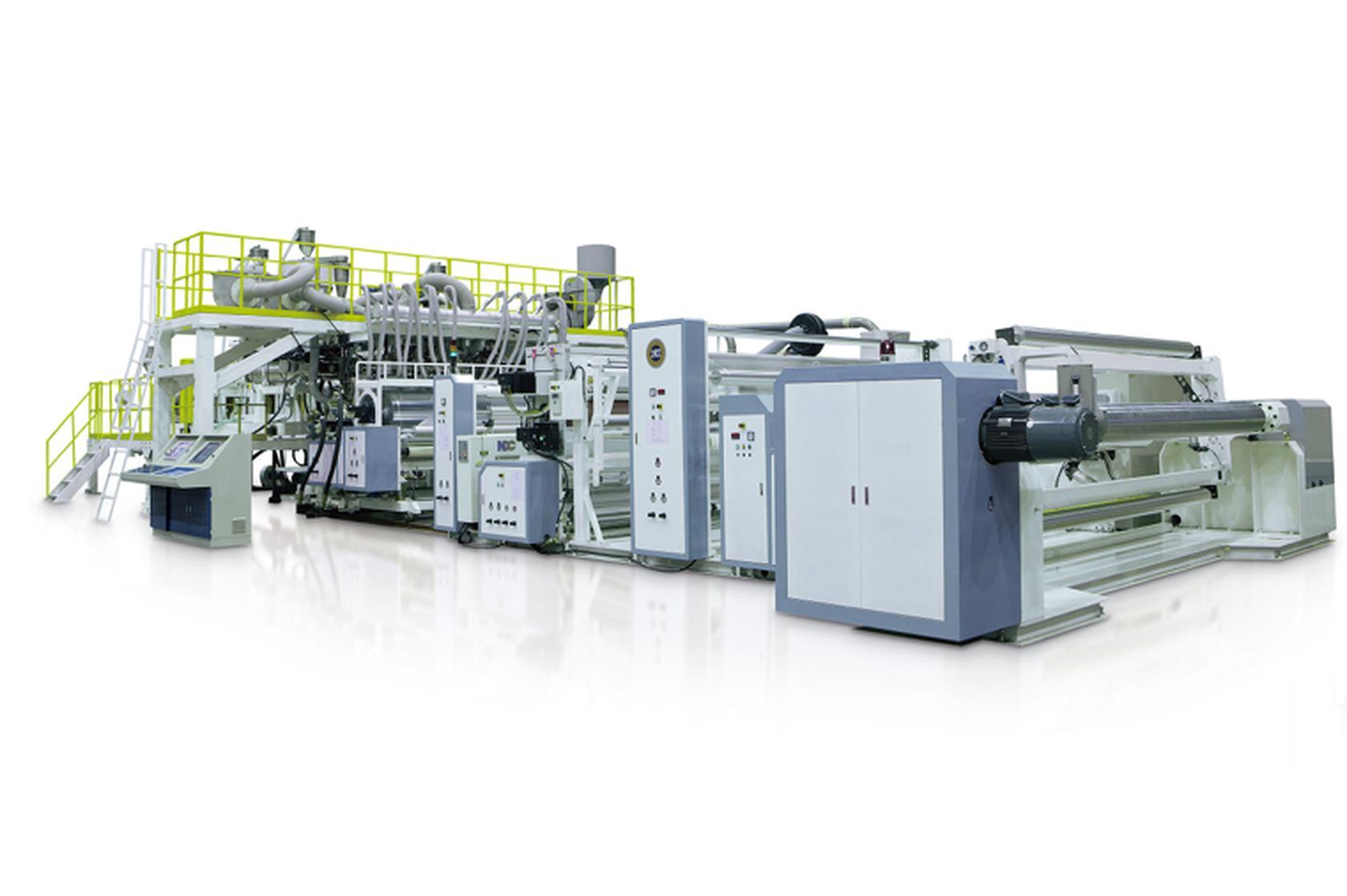

FKI-Mono/Multi-Layer Co-ExtrusionCast Film Making Machine

● Three-layer CPP film line, widths 2,000 / 2,500 / 3,000 mm, speeds 200 or 300 m/min

● Extruders with barrier flight screws & gear pumps for smooth, stable output

● European/US-made feed blocks & auto T-die with infrared gauging system ensure uniform thickness

● Cast cooling rollers (Ø800 or Ø1000 mm) tailored to line speed

● Automatic turret center winder with tapeless reel change & taper tension control

● Fully automated PLC + HMI system with remote access

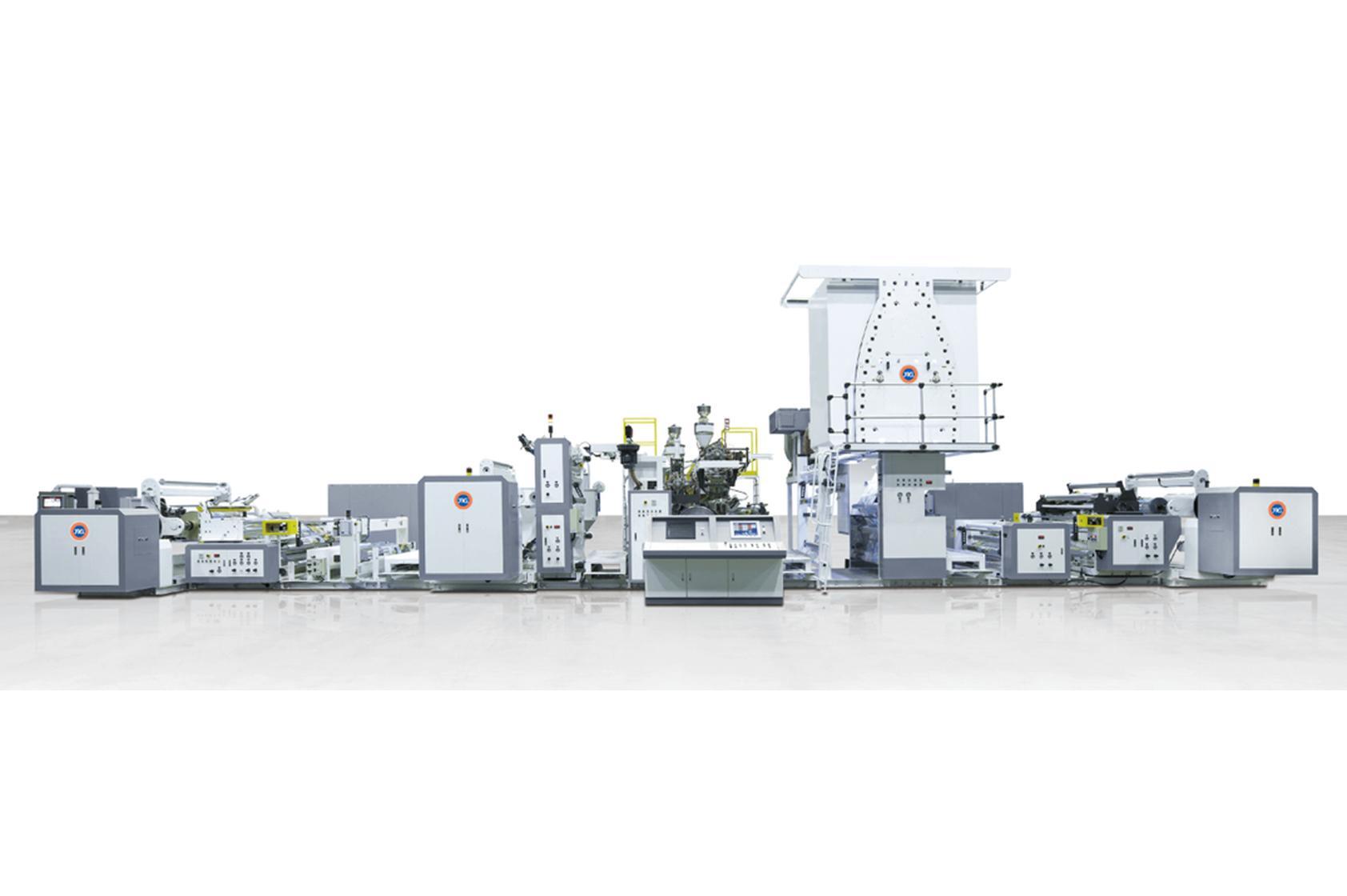

FKI-Mono/Multi-Layer ExtrusionLamination Machine

● Co-extrusion lamination line for flexible packaging films, 2–3 layers, speeds up to 350 m/min

● Screw design supports LDPE, PP, EVA, EAA & acid copolymers with stable high output

● Feed block & auto T-die from leading brands ensure precise coating with minimal thickness

● AC servo drives provide accurate line speed & stable tension control

● Automatic splicing & cutting on both unwinder/rewinder for uninterrupted production

● Rewinder supports both gap & contact modes

● Fully automated PLC + HMI system with remote access

Get the Perfect Match

Start your 1-on-1 meetings with FKI to explore new business opportunities.

Trusted Certifications for Quality Assurance

-2.png?width=300&height=300&name=%E6%9C%AA%E5%91%BD%E5%90%8D%E8%A8%AD%E8%A8%88%20(1)-2.png)

-1.png?width=300&height=300&name=%E6%9C%AA%E5%91%BD%E5%90%8D%E8%A8%AD%E8%A8%88%20(2)-1.png)

Stay Ahead of the Curve!

Subscribe Now for Exclusive Insights, Trends, and Offers Delivered Straight to Your Inbox!