ANKO | A Food Machine Manufacturer in Taiwan

Food Automation / Spring Roll machine / Customized Food Machine

Striving to bring safe and delicious food to the world with automation production solution.

ANKO was founded in Taiwan in 1978, and is committed to providing quality food production solutions. We believe that through complete turnkey planning and utilization of diverse production lines, customers can achieve success in their food businesses and together we will create unprecedented market opportunities!

Burrito Integrated Production Line

Empanada Making Machine (EMP-3000)

Create delicious, top-selling Empanadas with ANKO’s EMP-3000 Empanada Making Machine! This model produces up to 3,000 Empanadas per hour, reducing labor needs by 7-8 staff on the production line. Its high efficiency enables food factories and central kitchens to grow market share. Featuring a new filling system with an exclusive design, the EMP-3000 handles both raw and cooked ingredients, allowing easy flavor changes. FDA-approved forming molds ensure food safety, while its unique motion design boosts durability. ANKO also offers custom molds for logos or flavor markings. Flexible configurations, including a Dough Sheeting Machine, conveyor fryer, or packaging machine, allow for tailored production solutions.

Dimension: 8,050 (L) x 1,210 (W) x 1,968 (H) mm

Power: 5.32 kW

Capacity: 3,000 pcs/hr

Product name: Empanada, Curry Puff, Calzone

Product weight: 40-150 g/pc

Pastry thickness: 3-8 mm

Filling hopper capacity: 60 L

Air consumption: 450 L/min (@6kg/cm^2)

NW: 1,935 kg

Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

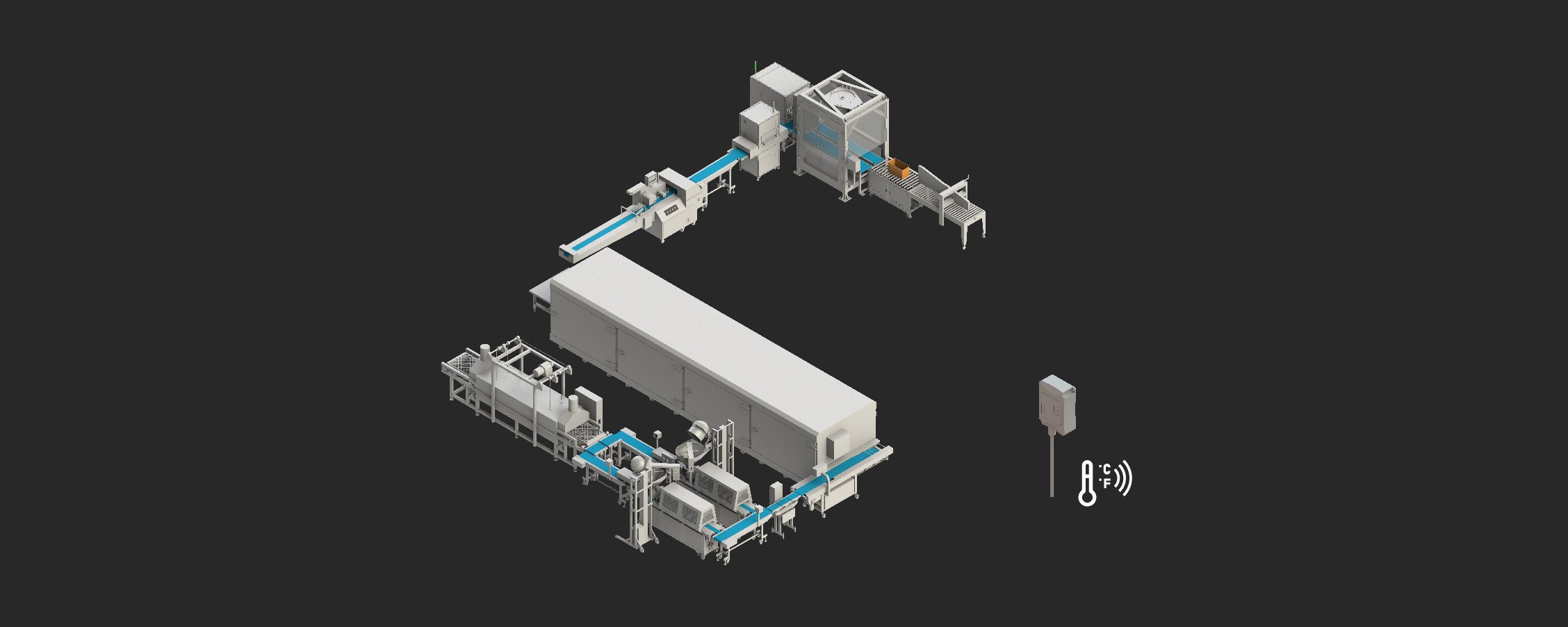

Spring Roll Production Line (SR-27)

ANKO SR-27 Spring Roll Machine is designed with proprietary mechanisms and is highly productive. It takes just 1.4 seconds to produce a perfect Spring Roll with few employees required for the production process. The new model operates with high stability and the filling system is the perfect solution for processing a wide variety of filling ingredients, such as vegetarian, cooked meats, and potato filling with different textures. Depending on your product requirements, ANKO’s machine can produce wrappers with different length, textures and apply the proper amount of filling into the Spring Rolls. The most petit Spring Rolls our machines can produce are at 7cm in length. This machine can also create a variety of different Spring Rolls to be sold as a frozen packaged good or served deep-fried and ready to eat. The parts in contact with food products are water resistant and can be thoroughly and quickly cleaned on a daily basis. ANKO’s SR-27 Spring Roll Machine has a capacity producing of 2,700 pieces per hour, and is suitable for large food factories, central kitchens, and high-volume manufacturers.

Specifications

Min. space required: 3,650 (L) x 3,050 (W) x 2,100 (H) mm

Power: 38 kW

Capacity: 2,400–2,700 pcs/hr

Product dimension (Choose one size only):

73mm: 25–32 (Dia.) x 73 (L) mm

85mm: 25–32 (Dia.) x 85 (L) mm

100mm: 25–32 (Dia.) x 100 (L) mm

Product weight (Choose one size only):

73mm: 22–26 g (varies depending on ingredient of filling)

85mm: 28–36 g (varies depending on ingredient of filling)

100mm: 40–50 g (varies depending on ingredient of filling)

Air consumption: 90 L/min (@ 4 kg/cm^2)

Weight (net): 1,800 kg

Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

Get the Perfect Match

Start your 1-on-1 meetings with ANKO to explore new business opportunities.

Stay Ahead of the Curve!

Subscribe Now for Exclusive Insights, Trends, and Offers Delivered Straight to Your Inbox!